PRODUCTS INFORMATIONSuper-precision stage HW series, patented

Super-precision stage HW series, patented

The feed mechanism incorporates a “ball screw + wedge type speed reduction mechanism”.This is a super-precise stage that achieves high follow-up*, high accuracy, and high stiffness by mounting a cross roller guide on the linear motion guide.

Features

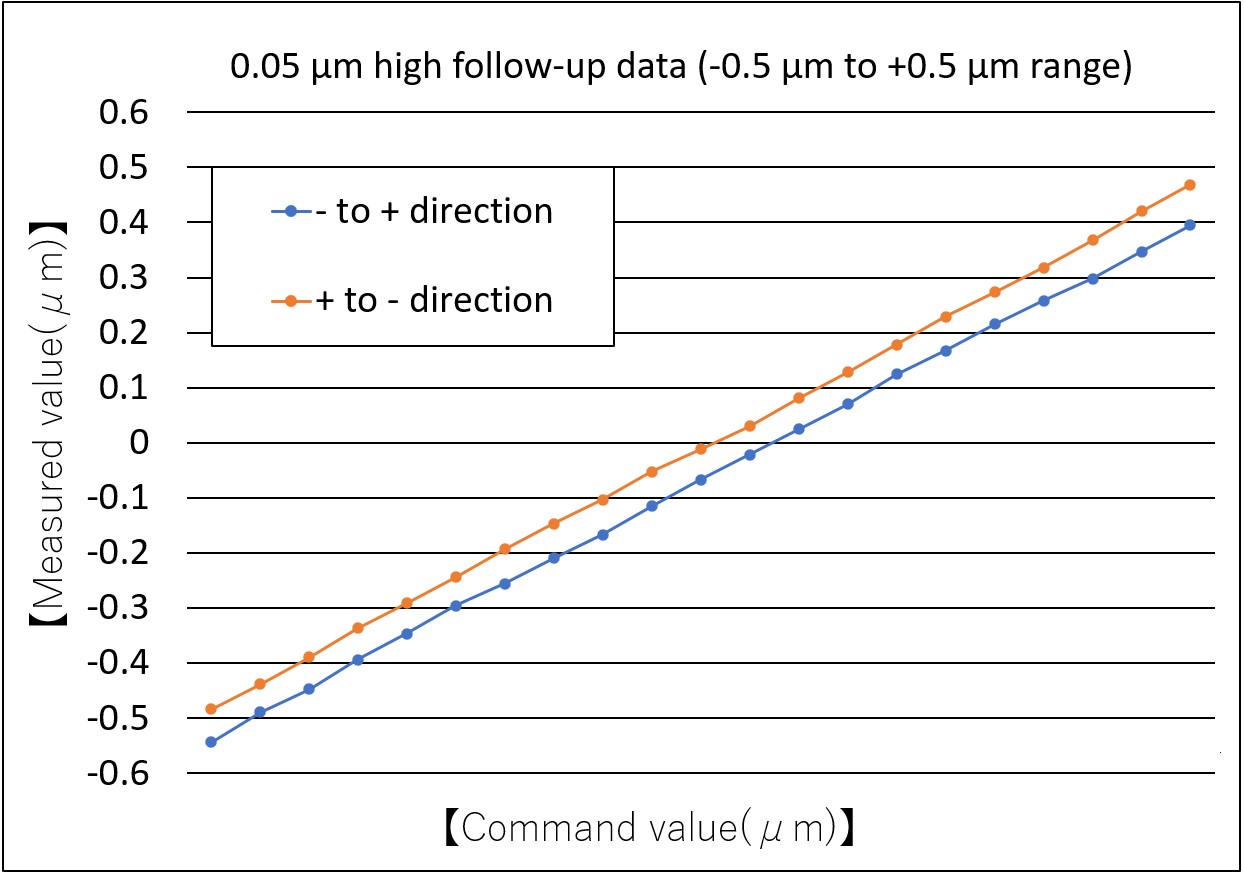

High follow-up capability

- 50 nm feed follow-up capability

*Follow-up capability is an important performance metric that measures the response accuracy of precision positioning stages to fine movement instructions. This parameter indicates how accurately the device can execute these instructions upon receiving minute movement command(less than 100nm). Especially in a series of continuous movement operations, the level of follow-up capability directly affects the overall reliability of the system. In applications requiring high precision, such as semiconductor manufacturing, follow-up capability becomes a crucial metric for assessing the performance of such devices.

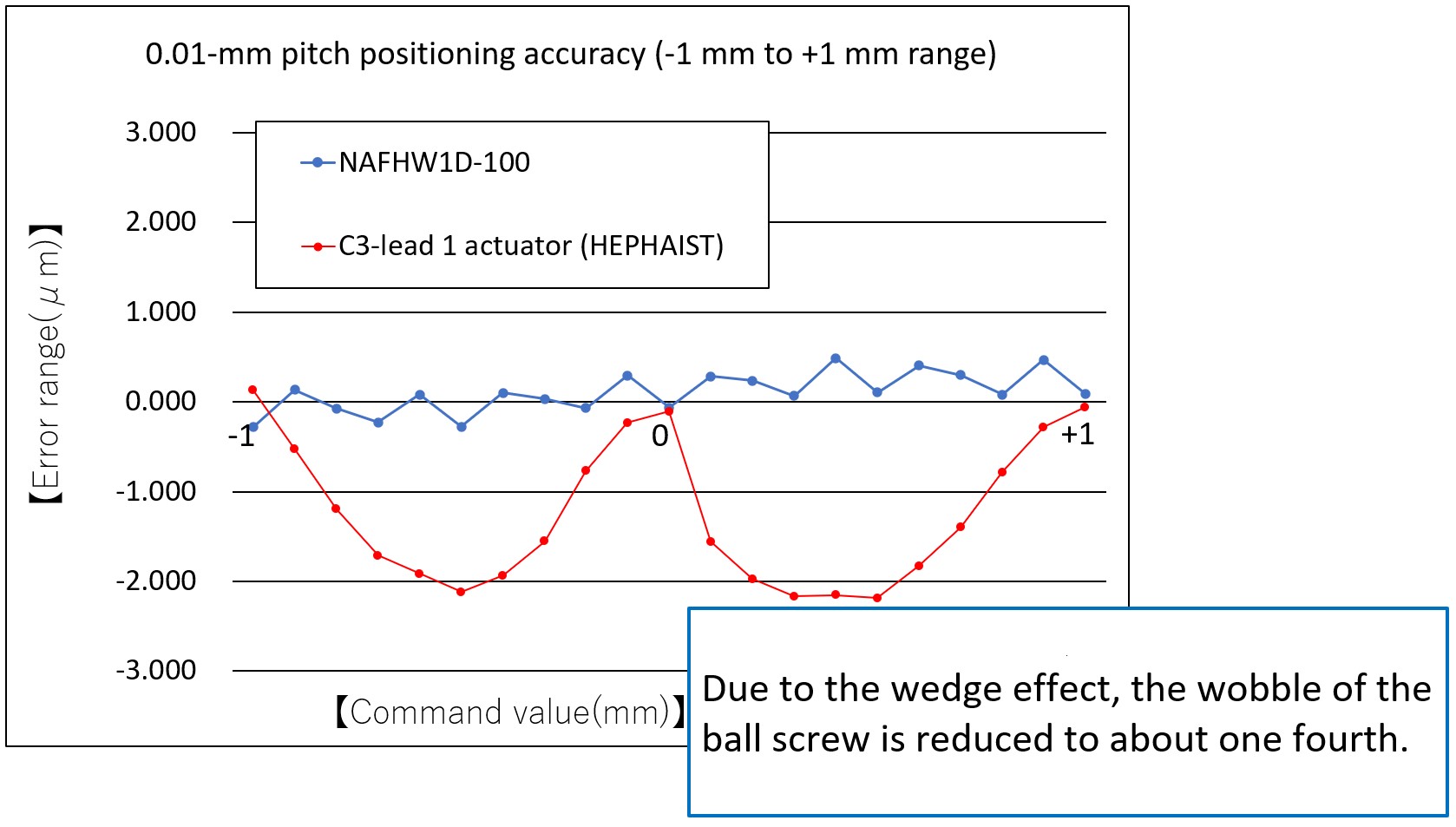

High positioning accuracy

- Achieve high resolution with the wedge-type speed reduction mechanism

- Reduce wobble of ball screw with the wedge mechanism

- Excellent straight motion performance with the cross-roller guides reducing sliding resistance

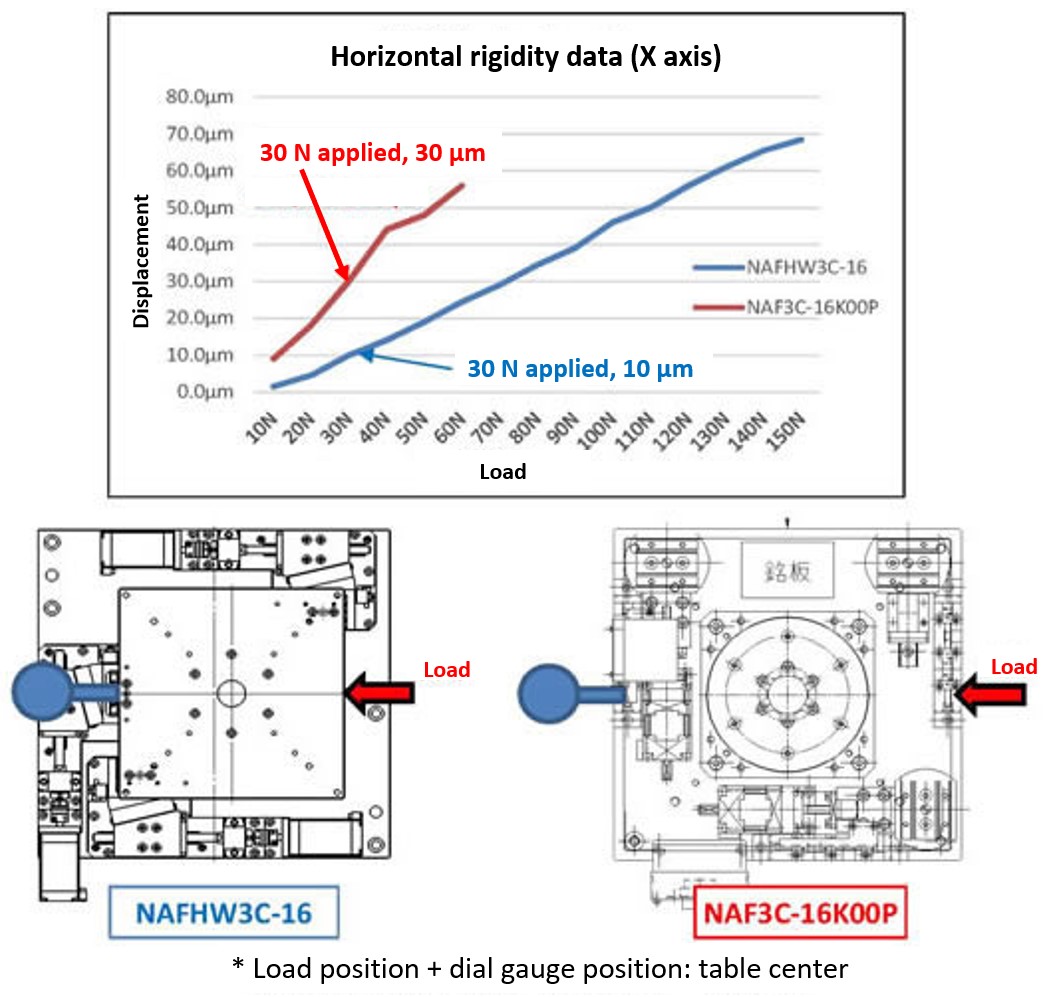

High stiffness

The 1/4 wedge structure increases stiffness by 1.5 to 2 times against lateral loads compared to existing products (NAF3C series)

Applications for Super-Precision Stages

- Semiconductor manufacturing equipment, various inspection equipment

- Optical system alignment equipment

- Nanometer positioning system, etc.

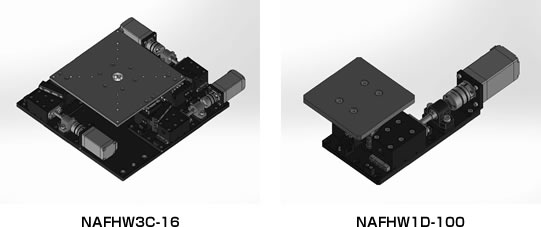

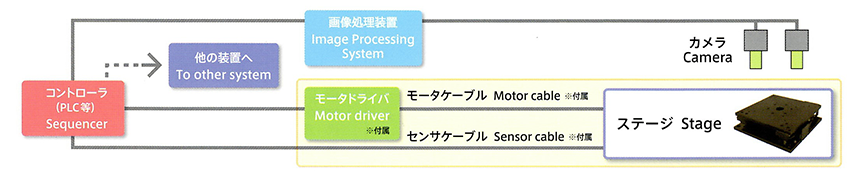

System Configuration Drawing

Product Specifications

| Product Specifications | Super-precision XYθ alignment stage | Super-precision single-axis stage |

|---|---|---|

| Properties | NAFHW3C-16 | NAFHW1D-100 |

| Stroke | XY axis:±1.4mm θ axis:±1.4° | ±3mm |

| Table size | 160mm×160mm | 100mm×100mm |

| Base size | 250mm×250mm | 143mm×80mm |

| Height | 61mm | 52.5mm |

| Absolute positioning precision ※1 |

XY axis:3μm θ axis:12sec | 3μm |

| Unidirectional repeatability | XY axis:±0.35μm θ axis:±1.5sec | ±0.25μm |

| Bidirectional repeatability | XY axis:0.70μm θ axis:3sec | 0.5μm |

| Follow-up capability ※2 |

50nm | 50nm |

| Static load capacity ※3 |

600N | 100N |

| Dynamic load capacity ※3 |

300N | 100N |

| Maximum speed | 1mm/sec | 1mm/sec |

| Degree of parallelism | 30μm | ー |

| Motor | Stepping:PK525PA(Product of ORIENTAL MOTOR) | |

| Servo:HG-AK0236(Product of Mitsubishi Electric) | ||

| Driver | Stepping:MC-S0514-3L(Product of MICROSTEP) | |

| Servo-amp:MR-J4-03A6(Product of Mitsubishi Electric) | ||

| Stage material | Iron-Low Temperature black chrome plating treatment | |

| Weight | 10kg | 1.5Kg |

| Lubricant | Low dusting grease | |

*1: Accuracy obtained when offset values from HEPHAIST are input.

*2: Resolution is set to 0.01 μm/pulse.

*3: The load capacity is for uniformly distributed load in the vertical direction.

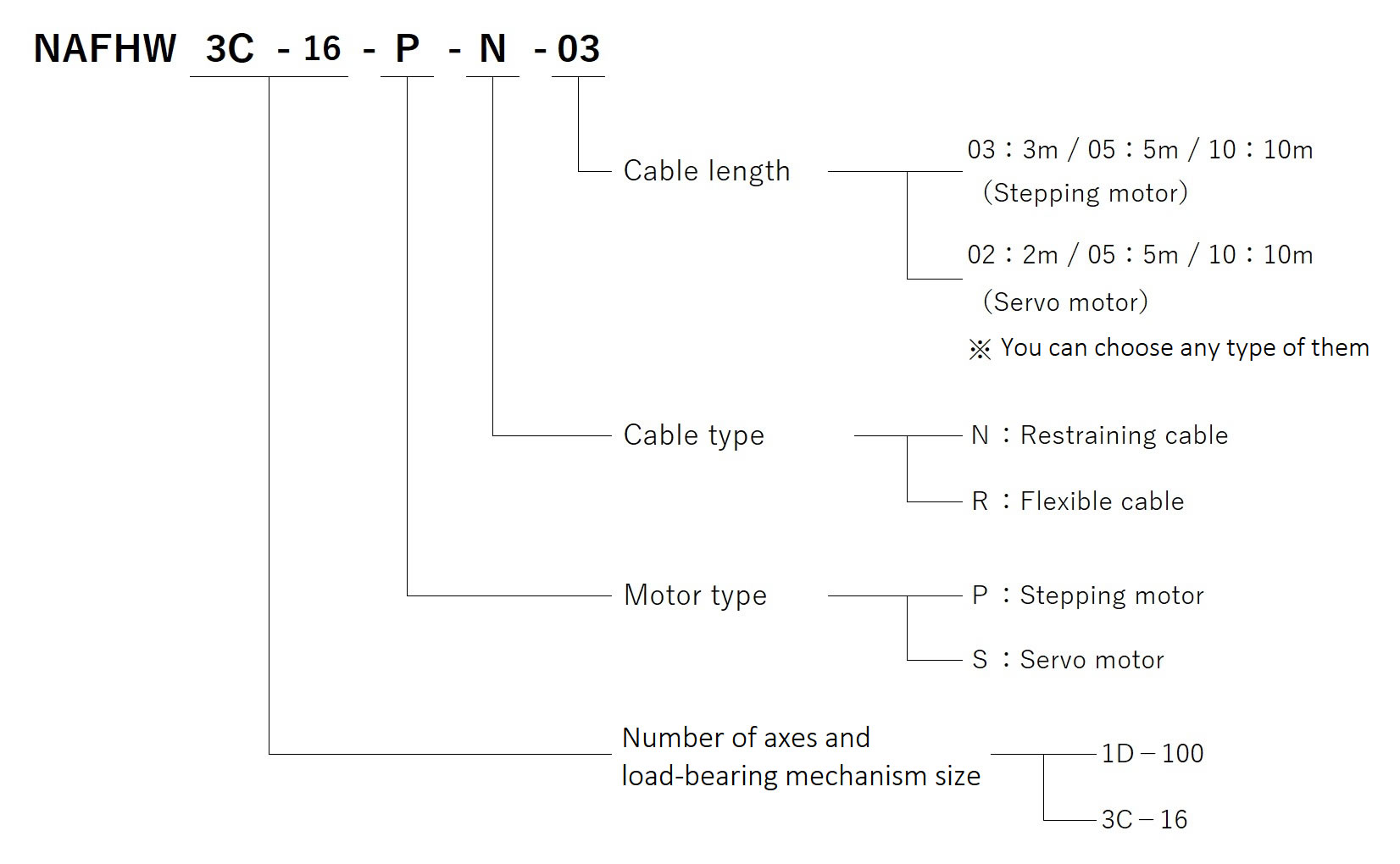

Model number notation